Preventing Weld Undercut: Proven Approaches Every Welder Need To Know

Preventing Weld Undercut: Proven Approaches Every Welder Need To Know

Blog Article

Understanding the Causes and Solutions for Undercut Welding in Metal Fabrication Processes

In the realm of steel manufacture procedures, the event of undercut welding postures a substantial obstacle that requires a thorough understanding of its reasons and sensible remedies. The detailed interaction of different elements during welding operations can result in this unfavorable phenomenon, impacting the architectural honesty and total high quality of the welded joints - Preventing weld undercut. By dissecting the origin of undercut welding and checking out efficient remedial measures, makers can raise the requirement of their workmanship and make certain the manufacturing of perfect metal parts

Typical Sources Of Undercut Welding

Regularly forgotten in steel fabrication, undercut welding occurs due to various variables that require meticulous attention and competence to be successfully minimized. In addition, improper welding techniques, such as using the wrong welding angle or travel speed, can also contribute to undercut formation. The choice of welding parameters, such as voltage, current, and wire feed rate, plays a substantial duty in the event of undercut welding.

Influence of Incorrect Welding Parameters

Imprecise welding criteria can dramatically endanger the honesty and top quality of bonded joints in metal construction processes. The impact of wrong welding criteria shows up in different methods, resulting in structural weak points and issues in the bonded elements. One vital element affected by improper welding criteria is the infiltration deepness of the weld. Insufficient heat input as a result of reduced welding currents or excessively high travel rates can lead to inadequate blend in between the base metals, resulting in incomplete joint infiltration and compromised bonds. Conversely, too much warm input brought on by high welding currents or slow-moving traveling rates can lead to burn-through and too much support, producing a brittle and unpredictable weld framework. In addition, inaccurate criteria such as incorrect voltage settings or inaccurate electrode angles can contribute to irregular weld bead accounts, lack of blend, and enhanced opportunities of problems like damaging. As a result, meticulous interest to welding parameters is extremely important to guarantee the manufacturing of premium welds with the wanted mechanical buildings and structural stability.

Effect of Improper Torch Angle

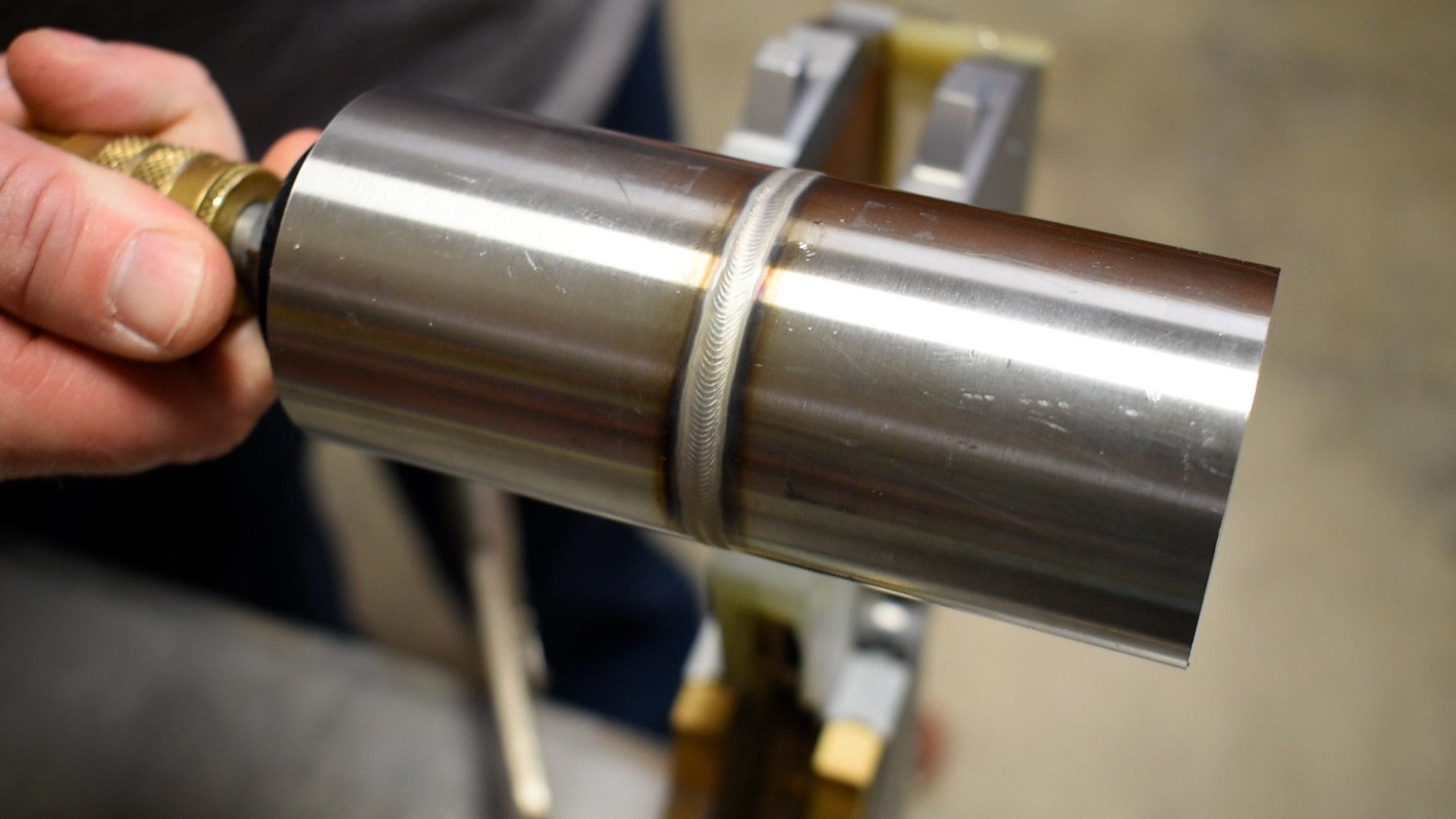

Improper torch angle in welding operations can considerably impact the quality and integrity of the final weld joints in metal fabrication processes. The lantern angle plays a crucial role in identifying the heat input and distribution during welding. When the lantern angle is wrong, concerns such as damaging can develop. Undercutting is a common welding defect where a groove forms along the weld toe, weakening the joint and endangering its architectural stability.

A torch angle that is also high can cause insufficient penetration, insufficient combination, and enhanced spatter. On the other hand, a lantern angle that is as well shallow can cause extreme penetration, burn-through, and distortion of the base product. Preventing weld undercut. Appropriate torch angle is essential for making certain constant weld quality, toughness, and look

To avoid damaging and various other defects triggered by incorrect lantern angles, welders need to be trained to keep the appropriate lantern angle throughout the welding procedure. Regular tracking and adjustment of lantern angles during welding can aid accomplish audio welds with very little issues.

Function of Inadequate Welding Strategies

One more aspect of inadequate welding techniques is improper weld prep work. Poor cleansing of the base steels, inaccurate joint design, or insufficient edge prep work can all add to damage welding. Additionally, insufficient shielding gas coverage or making use of the incorrect kind of why not try these out gas can result in incomplete blend and the development of undercut problems.

To attend to the function of insufficient welding techniques in steel construction processes, it is vital to give detailed training for welders. Proper education and learning on welding specifications, joint preparation, and securing gas choice can aid stop undercut welding and guarantee high-quality welds in steel fabrication tasks.

Efficient Solutions for Undercut Welding

Addressing undercut welding in steel fabrication calls for executing reliable services to boost weld high quality and architectural integrity. Among the primary options to fight undercut is to readjust welding parameters such as voltage, present, and take a trip speed to make certain proper warmth input and fusion. By fine-tuning these settings, welders can protect against extreme melting of the base steel and filler material, decreasing the chance of undercut formation.

Furthermore, correct joint preparation is critical in avoiding undercut. Making sure tidy base metal surfaces free of pollutants and making use of the appropriate bevel angle can assist advertise far better weld penetration and decrease the danger of undercut - Preventing weld undercut. Using suitable welding techniques, such as oscillating the lantern or weaving, can additionally aid in distributing warm equally and loading the weld joint properly, lessening the opportunity of undercut issues

Furthermore, selecting the appropriate welding consumables, including electrodes and filler steels, is necessary in minimizing undercut. Using materials with appropriate chemical compositions and mechanical residential properties can add to attaining audio welds with marginal undercut. Normal examination and quality control measures should also be implemented to spot and deal with undercut issues quickly, guaranteeing the overall integrity of fabricated steel parts.

Final Thought

In final thought, comprehending the causes and solutions for undercut welding in steel manufacture procedures is important for accomplishing premium welds. By dealing with common reasons such as wrong welding specifications, improper lantern angle, and poor welding methods, welders can avoid damaging and make sure strong, durable welds. It is important to take notice of browse around this site these aspects and execute effective remedies to enhance the overall welding procedure and end product high quality.

Report this page